Aseptic Fill & Finish Services for Injectables in Clinical Trials

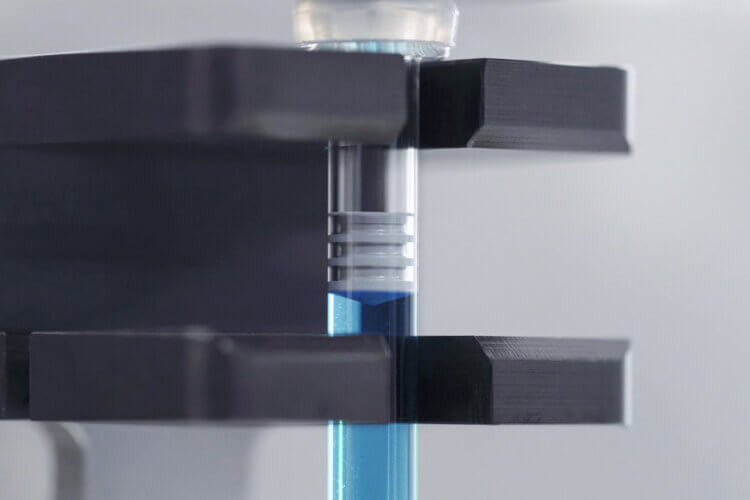

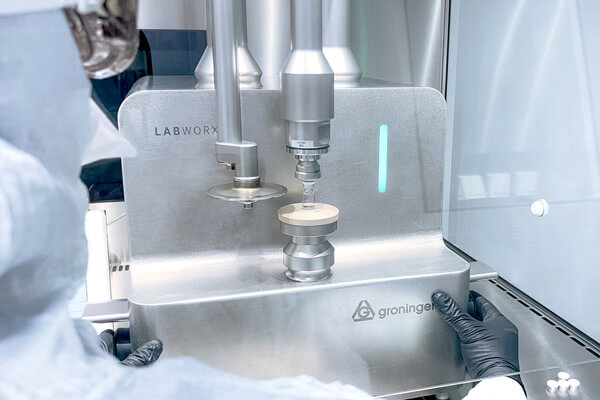

In the area of clinical trials, we offer contract filling of small batches under LF as well as in safety workbenches, either manually or with highly flexible semi-automatic filling and closing equipment from groninger and Berner (safety) workbenches.

These processes, mainly for filling vials in phases 1 and 2, offer our customers the greatest possible flexibility and an enormous time advantage. Hereby, we support our customers with sterile filling (GMP and non-GMP) – including engineering batches, stability tests as well as verification of container closure integrity.

For phase 3, we offer aseptic filling for glass or polymer vials, syringes or cartridges. The filling processes developed and applied in the clinical phases, including all common gassing and vacuum options, can subsequently be scaled up to our commercial groninger production lines through a simple, cost-effective and fast technology transfer.

Project requests to Thorsten Häfner

E-mail: service@psm-saar.de

Our End-To-End CDMO Services for Clinical Trials

- Process and method transfer from development partner

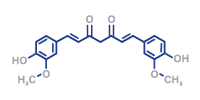

- Feasibility, E&L, CCI studies under GMP conditions

- Semi-automatic aseptic GMP filling for syringes, vials, or cartridges

- Visual inspection, labeling, and final packaging

- Analytical services

- Terminal sterilization

- Cold storage down to -80 °C for API and 2-8 °C for finished product

- GMP storage and GDP transport