Peptides: Precision Molecules Shaping the Future of Medicine

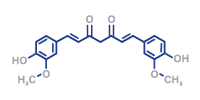

Peptides are short chains of amino acids that act as key signaling and messenger molecules, regulating numerous biological processes in the body. They play a critical role in controlling growth, metabolism, immune responses, and hormonal activity. Due to their high specificity, targeted mechanisms of action, and generally good tolerability, peptides are becoming increasingly important in modern drug development.

In research and therapy, peptides open new possibilities: they can modulate pathological processes without harming healthy cells. In oncology, for example, peptides can recognize tumor cells and serve as carriers for therapeutic agents.

In diabetology, they support the regulation of blood sugar and insulin release, while in endocrinology, they can precisely influence hormone balance. Peptide-based therapies also offer innovative and precise solutions for metabolic and rare diseases.

The versatility of peptides makes them a cornerstone of modern medicine. Their ability to precisely control biological signals enables the development of tailored therapies that are both effective and well-tolerated. With ongoing research and technological advances, peptides are poised to play an increasingly central role in personalized medicine.

The following facilities and processes are implemented for handling peptides:

- Storage of APIs at −80 °C

- Controlled thawing process using HOF thawing units

- Single-use compounding with batch sizes of up to 100 L

- Sterile filtration with single-use filters and product tubing, including PUPSIT

- Use of all common pre-sterilized packaging, such as PFS syringes, vials, or cartridges

- Filling in a sterile Class A cleanroom using state-of-the-art Groninger filling technology

- Optical inspection, CCIT, and packaging

- Cold storage and GDP-compliant transport at 2–8 °C

With the Robocell filling system from Groninger and SKAN, we can fill batch sizes of up to 100 liters. We offer maximum flexibility in processing ready-to-use syringes up to 10 ml, vials up to 50 ml, and cartridges up to 10 ml in glass or polymer, while ensuring minimal product losses with 100 % check weight control.

With the Groninger Flexfill filling system, we can fill batch sizes of up to 600 liters. We offer maximum flexibility in processing ready-to-use syringes up to 50 ml, vials up to 100 ml, and cartridges up to 10 ml in glass or polymer. This line is equipped with peristalitc and rotary piston pumps and various gassing and vacuum options.