Biosimilars – Injectables in Vials, pre-fillable Syringes (PFS) and Cartridges

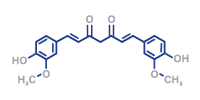

A biosimilar is a biological medicine highly similar to an already approved reference product. It contains the same active ingredient, such as a monoclonal antibody or protein, and aims to deliver the same efficacy, safety, and quality.

Due to their complexity, biologics cannot be exactly copied, so biosimilars undergo extensive testing of structure, function, efficacy, safety, and immune response. They provide cost-effective alternatives to established biologics.

Unsere Prozesse und Anlagen für Biosimilars:

- Storage of APIs at −80 °C

- Controlled thawing process using HOF thawing units

- Single-use compounding with batch sizes of up to 100 L

- Sterile filtration with single-use filters and product tubing, including PUPSIT

- Use of all common pre-sterilized packaging materials, such as PFS syringes, vials, or cartridges

- Various pumping systems, stopper placement via vacuum or insertion tube, and optional gassing

- Filling in a sterile Class A cleanroom using state-of-the-art Groninger filling technology

- Visual inspection, CCIT, and packaging

- Cold storage and GDP-compliant transport at 2–8 °C

With the Robocell filling system from Groninger and SKAN, we can fill batch sizes of up to 100 liters. We offer maximum flexibility in processing ready-to-use syringes up to 10 ml, vials up to 50 ml, and cartridges up to 3 ml in glass or polymer, while ensuring minimal product losses with 100 % check weight control.

With the Groninger Flexfill filling system, we can fill batch sizes of up to 600 liters. We offer maximum flexibility in processing ready-to-use syringes up to 50 ml, vials up to 100 ml, and cartridges up to 3 ml in glass or polymer. This line is equipped with peristalitc and rotary piston pumps and various gassing and vacuum options.