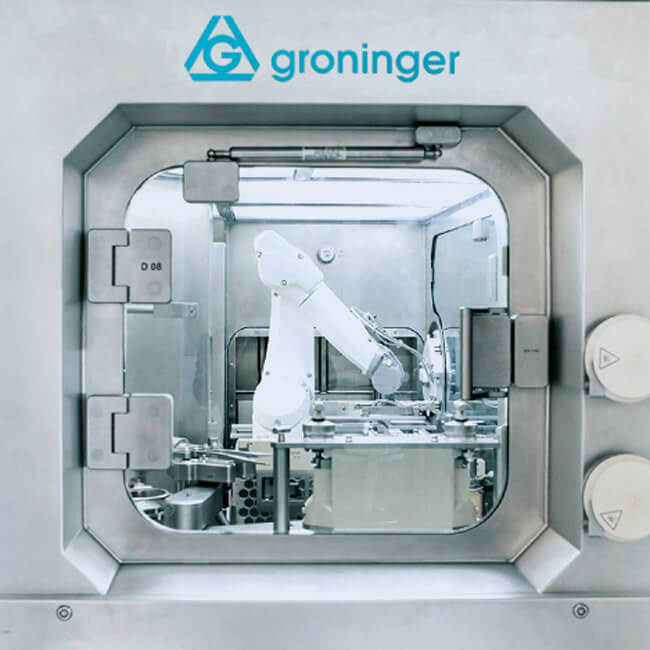

The human factor is a critical risk in the pharmaceutical industry: In the complex world of pharmaceuticals, precision matters. But so does safety. Groninger and SKAN developed a gloveless, fully automated filling line based on robotic technology. The robocell, addresses this challenge by reducing the risk of contamination from human intervention in the aseptic filling process to an absolute minimum. All manual processes are replaced by various robotic technologies that provide maximum safety. The robocell can be used from the beginning of drug development through the clinical phases and scaled-out to commercial production. By eliminating human intervention, manufacturers can ensure their products meet the highest quality standards while maintaining process safety, operator safety and compliance with Annex 1. Watch this video to find out more about the robocell and learn about its benefits and possible applications.