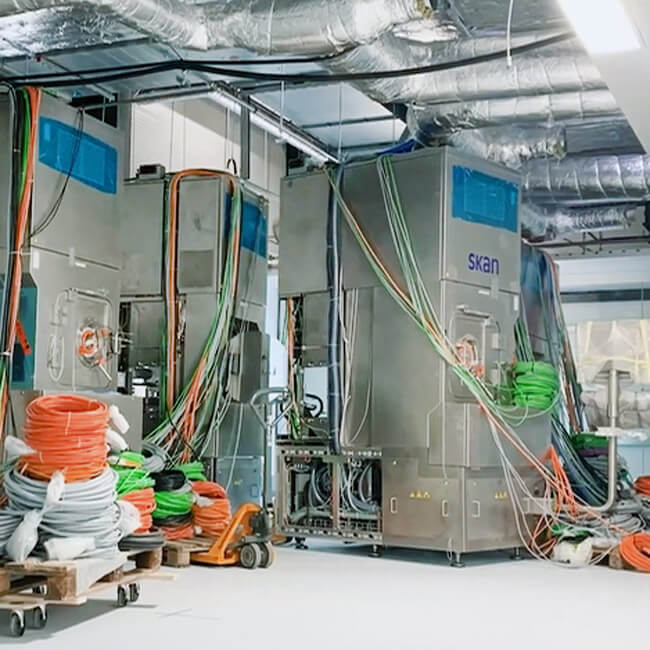

We are pleased about the delivery of the robocell, another milestone in our expansion project has been reached. The hard-working employees of SKAN, groninger and PSM are joining forces to install the system.

With the latest generation of aseptic filling systems, all current regulatory requirements of the pharmaceutical industry are met. In cooperation with the company SKAN, groninger developed a gloveless, fully automated filling line based on robot technology. Human intervention in the core processes of pharmaceutical filling is now a thing of the past. Whether installing a filling path or the handling of active and passive viable air monitoring – the robocell carries out these processes automatically without human interventions. This increases process reliability and sterility assurance drastically especially when processing high potent drugs, viral victors, cell & gene drugs, and others in our Pharma 4.0 CDMO plant in Schiffweiler/Germany.

Especially with regard to the revision of the EU GMP Annex 1 draft, robocell sets standards:

- The reduction / elimination of human intervention in the aseptic filling process.

- The use of intelligent robotic solutions

- The support of a holistic Contamination Control Strategy (CSS)

The contamination control strategy in particular is an essential element for pharmacists and contract fillers. For this reason, during development groninger placed great emphasis on providing the best possible support for customers and users of the robocell. Detailed CFD analyses of all critical areas as well as the joint development of isolator and filling system ensure that possible contamination is downgraded to a technically minimal risk.

Highlights of the robocell

- Maximum flexibility in the use of packaging materials

- Shortest set-up times enable highest OEE values in segment comparison

- Insertion and installation of parts that come into indirect contact with the product

- The implementation of a PUPSIT in robot-assisted lines